Location: Bridgwater

Project Type: Shafts

Client: Wessex Water

Project Duration: 15 months

Contract Value: £4.5m

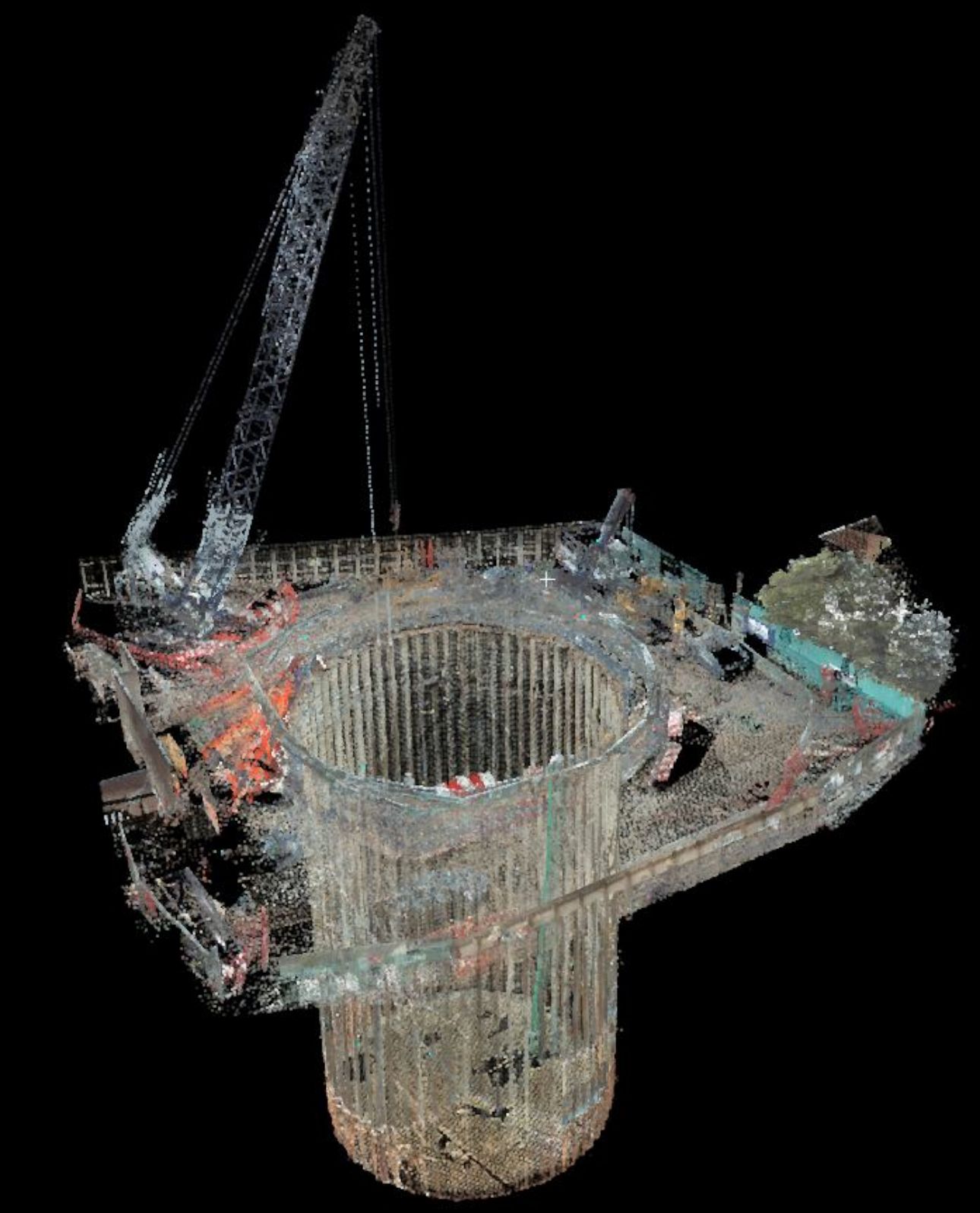

A 15m diameter, 26m deep Storm Water storage shaft with a capacity of 3M litres was constructed on a tight town centre site in Bridgwater, in challenging ground conditions over a period of 15months. Full ECI engagement from our client, Wessex Water allowed a full Contractor led design from the outset.

Ground conditions consisted of soft silty river Alluviums over a layer of Artesian River Terrace Gravels, overlaying Mercia Mudstone. Envolve developed the concept of constructing a segmental shaft within a Secant Piled structure on a full Design & Build basis.

Specialist piling contractor Cementation were engaged to design and construct the Secant Pile shaft. A 160t BG42 piling rig was mobilised to install 68No 1180mmØ, 30m long rotary Concrete piles. Piling tolerances of 1:200 verticality and 25mm position had to be achieved to ensure that sufficient hoop strength could be attained to allow the excavation of the shaft without the need for additional support or propping.

The scheme is the biggest secant shaft in the country and the photo opposite featured on the front cover of ‘Ground Engineering’ magazine.

It was necessary to hang these structures at a high level within the shaft, supported by corbels. Pre-cast concrete sections were used to form the smooth shaft lining before an insitu reinforced concrete wet-well was cast approximately half way up. A precast screening channel was then lowered in, spanning between the wet well and the incoming sewer.

The shaft was covered by a composite precast/ insitu coverslab, supported by a structure of 20t precast concrete beams. Bristol Road was a difficult and challenging project that was delivered to outstanding H&S Standard’s and was testimony to early contractor involvement and an aligned Project Delivery Team.

Envolve received high commendation from Wessex Water on the successful delivery of the scheme:

“A great result, well done… , a significant achievement when you consider all the challenges. Please pass on my thanks to everyone involved.”

“Many thanks for this, excellent achievement. This scheme was always a challenge but the whole team has pulled together and delivered.”

A full time surveyor continually checked the installation criteria using conventional, electronic, laser and digital devices. Piling was completed in approximately 3months, and excavation commenced immediately following. Pile as-built positions were checked throughout excavation, with a full laser survey completed at formation.

The predicted pile interlock was well within the specified tolerances allowing excavation to full depth without intermediate support. The base slab was then constructed, allowing the pre-cast liner to follow on. Our in-house Shaft Construction team ensured we could offer savings over employing an external subcontractor, guaranteeing value is passed on to the Client.

Holdenhurst WRC

A £30 million investment by Wessex Water to protect Bournemouth's popular beaches

Location: Bournemouth

Project Type: Water Treatment

Client: Wessex Water

Project Duration: 24 months

Contract Value: £14.5m

Holly Hedge Animal Sanctuary

Its amazing to see how our time can benefit the sanctuary and its residents.

Location: Holly Hedge Animal Sanctuary

Project Type: ESG

Client: Community Volunteering

Project Duration: 1 day!

Contract Value: £0